| Part Number | ESOSML31-S50C | Distance | 500m |

| Form Factor | QSFP112 | Connector | MPO - 12(APC) |

| Wavelength | 1310 | Transmitter | EML |

| Receiver | PIN | Media | Single-Mode Fiber?(SMF) |

| Power Consumption | <1.2W | Protocol | 400G Base Ethernet |

| Case Temperature(℃) | C: 0℃ to +70℃ |

Silicon photonics integrated solution with optical DSP CDR inside

Hot-pluggable QSFP112 form factor

4x106.25 Gbps electrical interface

Maximum link length 500m on SMF fiber with FEC

MPO-12 APC connector

+3.3V single power supply

Power dissipation <12W

Operating case temp Commercial: 0°C to +70 °C

RoHS compliant

The 400G QSFP112 DR4 1310nm module delivers ultra-high bandwidth with 400Gbps data transmission over single-mode fiber up to 500 meters. Featuring an MPO-12 connector and PAM4 modulation, it is engineered for the scalability demands of hyperscale networks. Its low-latency design and efficient power profile make it a preferred solution for AI/ML workloads and advanced cloud infrastructures. The robust architecture ensures reliable signal integrity, helping operators build future-ready high-capacity networks.

Artificial Intelligence and Machine Learning Clusters

AI training and inference clusters demand rapid east-west traffic between GPUs and CPUs. The 400G DR4 module supports ultra-fast data transfer across high-density server nodes, ensuring that workloads like deep learning, natural language processing, and real-time analytics run without bottlenecks. Its power-efficient design reduces the energy footprint in GPU-intensive environments.

Cloud-based Storage and Virtualization Platforms

With increasing demand for real-time storage access, virtualization, and data replication, the 400G DR4 ensures seamless connectivity across multiple racks in data centers. The 500m transmission capability allows operators to connect storage systems to compute nodes efficiently, minimizing downtime and improving performance in mission-critical applications.

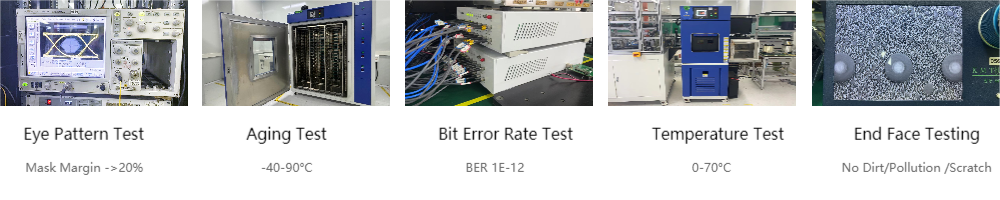

ESOPTIC is equipped with a comprehensive range of professional testing equipment designed to assess various parameters of optical products.

This ensures the highest performance, quality, and stability of optical transmission in all of our products.

Packing of module products

Put the qualified products into the corresponding model blister box packaging.

The bottom, surface and side of the carton are filled with one piece of anti-static foam to protect the product.According to the requirements of the packing quantity, put the blister box box of the product into the packaging carton. If the space between the blister boxes is large, use a piece of anti-static foam to put it in the middle. The empty space in the end box must be filled with anti-static foam to ensure that it will not be damaged during transportation.

The outer case label is attached to the side position of the outer case,Label the outer case after sealing.

At the time of delivery, the entire outer box should be wrapped with at least 2 layers of wrapping film protection.